Compost-Flow Design Process

Composting is a highly sustainable way to reduce garden and food waste, but many users struggle to do it effectively. Poor understanding of the process often leads to slow decomposition, unpleasant odours, pest issues, and ultimately low-quality compost. These frustrations discourage continued composting and reduce its environmental impact.

To understand composting behaviour and user challenges, I analysed existing composters, studied ideal composting conditions and conducted user interviews and surveys to identify common frustrations and gaps in knowledge.

Research & Insights

Ideal ratio of brown to green waste is 2:1

Key user survey results

Perceptual Map of existing composters

Design Development

Intitial Concepts

Concept Development

Prototyping Development (3D printing and Foam models)

Final Prototyping & Testing

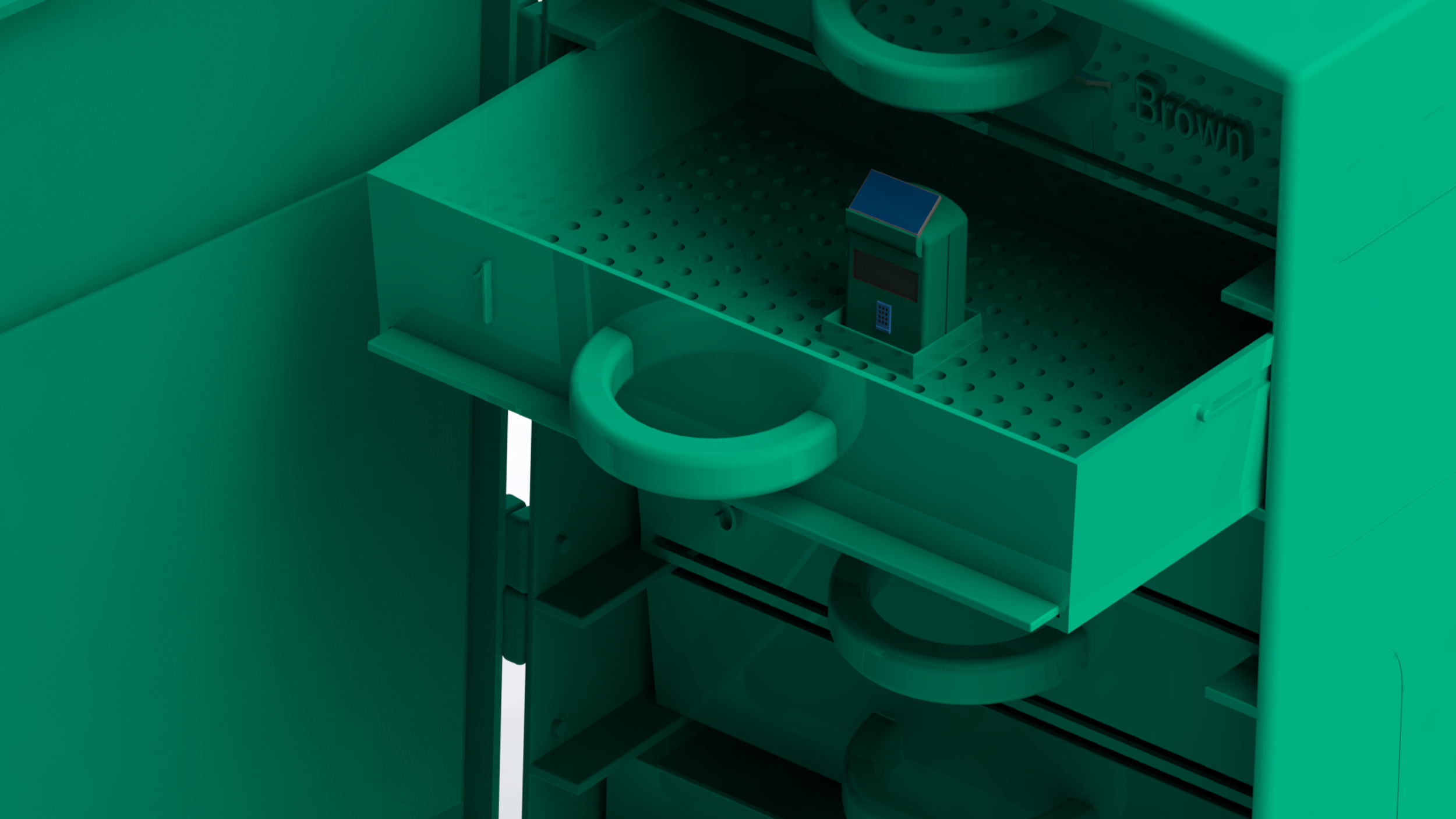

Test Rig prototype set up in the garden using 2 sieve trays to investigate the speed of decomposition, what type of waste material decayed the fastest and if the sieve tray system was a suitable design option.

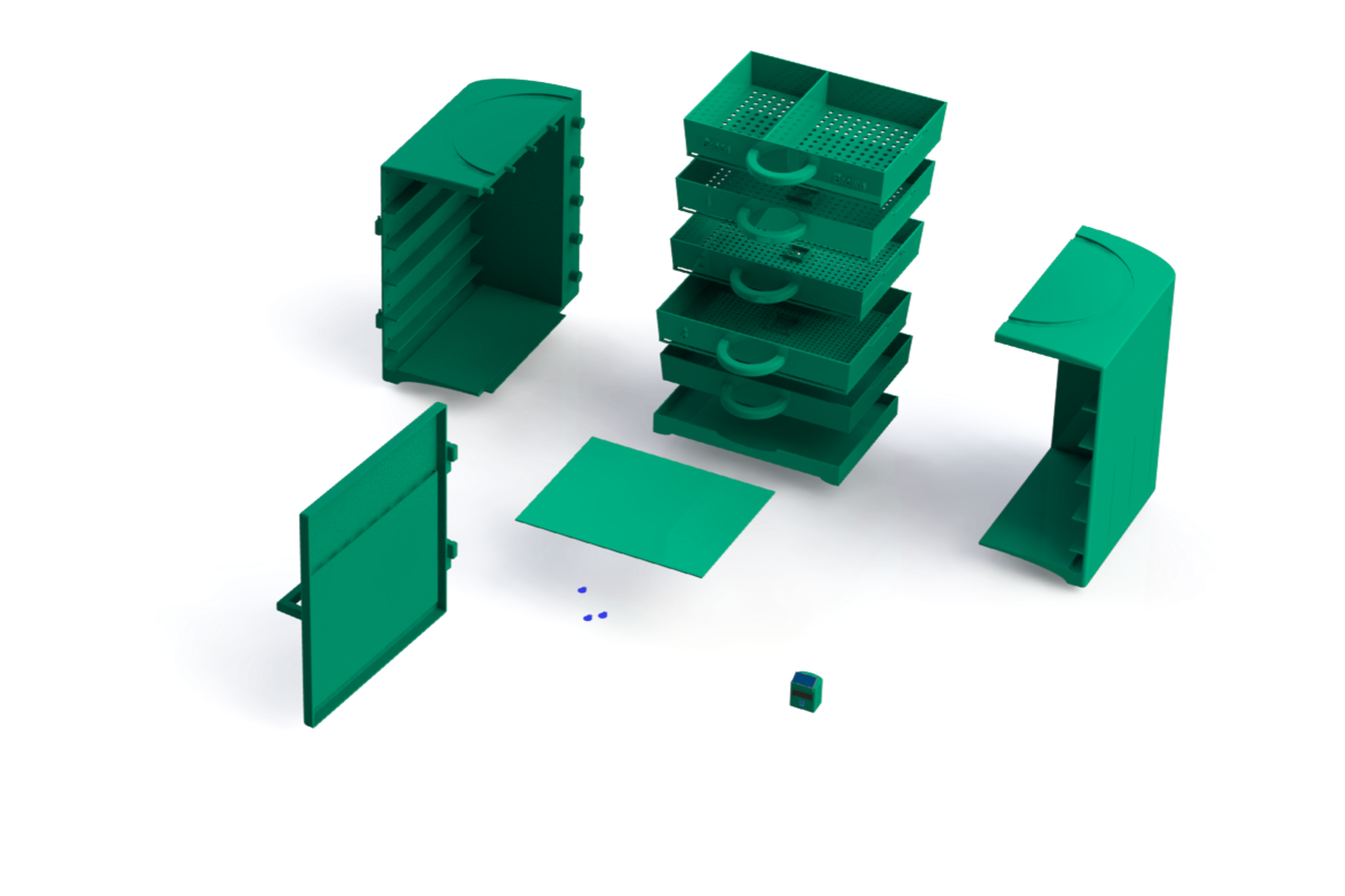

Final prototype production of the 1:5 scale aesthetic model, using PLA, Polyjet and FDM 3D printing methods, all parts then sanded, primed and spray painted.

Final Outcome

Future Development

I am planning to develop this product further based on feedback I receieved, tweaking parts of the design and construct a full scale prototype to properly test to see if it is suitable and potentially kickstart the project. The product was formely known as Compo-Flow, however the name of the system as a whole was renamed to Compost-Flow, with each individual prdouct being given its own name.